When you use a sewing machine, there are several maintenance things that are important to know to keep it running smoothly. One of those items is how to oil a sewing machine. Maybe you’ve been sewing for a long time and never oiled the machine. Did you know that failing to clean and oil the machine might actually cause it to break down or simply not work as well?

Your machine needs to be cleaned and oiled on a regular basis. How often really depends on how much you use the machine and the fabrics that you work with. In this guide, we will walk you through how you can clean your sewing machine and how to properly oil it. Follow this guide to help you get it done right!

When you sew, materials shred, and so does your thread. While you might not really notice it as you go, it’s building up in the depths of your machine. Those piles of thread-shedding pieces could eventually affect your machine. If nothing else, it could cause your stitches to get off, cause other fabric to end up in a stitch, or even make it not work well.

This is why cleaning is so important. it helps to remove all of that shed. So be sure to clean your machine regularly, especially if you are using it frequently. And even if you don’t use it that often, it really still needs to be cleaned at functional intervals.

The first step of the cleaning process is the crochet area. You might hear this referred to with different terms, but it’s generally referring to that space right beneath your foot presser and needle.

Down inside that space, it’s easy for thread, fabric, and shedding to pile up and accumulate. You can use a simple cleaner like this Mega Genie bobbin washer to help get your bobbin shiny and clean in the process. Many people will use a small brush, like a small paintbrush, to dust inside around and inside that bobbin space. Be sure to get all the tiny crevices of the bobbin and crochet area.

Be sure to finish up by oiling this area as well.

Once the crochet and bobbin are clean, you want to get the interiors that are harder to see and access. Some of these might rest behind the bobbing, but it will vary by machine. Since these crevices are small and tiny, they can be hard to see and get into. But your fabric that sheds has absolutely no problem finding its way inside.

Open up the sewing machine beneath the footplate, and use that brush to get in there and dust it all out. Your user’s manual can also walk you through the cleaning or how to access the trickiest of places too.

The foot pedal is easier to access, but it is often overlooked for cleaning purposes. We recommend taking the foot pedal off and thoroughly cleaning it, and wiping it down. This gives you a chance to get off any dirt or debris and clean the screws and areas that hold it in place too.

You might be surprised just how much dirt and grime are on there that you couldn’t see. Once you clean it, go ahead and lubricate it, as well as the moving parts around the foot pedal, so they all move seamlessly when you’re working.

Cleaning is just one part of the job. Now, you also need to oil different parts of the machine. If your sewing machine sounds weird, there is likely a reason for it. Sometimes, it could be from parts not working properly, pins dropped inside, things put together wrong, or it could just be that your machine needs to be oiled.

If you’re troubleshooting those strange sounds, try oiling to see if it makes a difference. How often you need to oil the machine depends on how much you use it. On average, it is recommended that you oil your machine every 2-3 bobbin changes worth of use.

Whether you have a professional sewing machine, or something totally different, every machine is unique by design. Be sure to refer to your owner’s manual for the proper oiling process and locations. You also need to make sure you use an oil that is suitable for your machine to avoid causing damage.

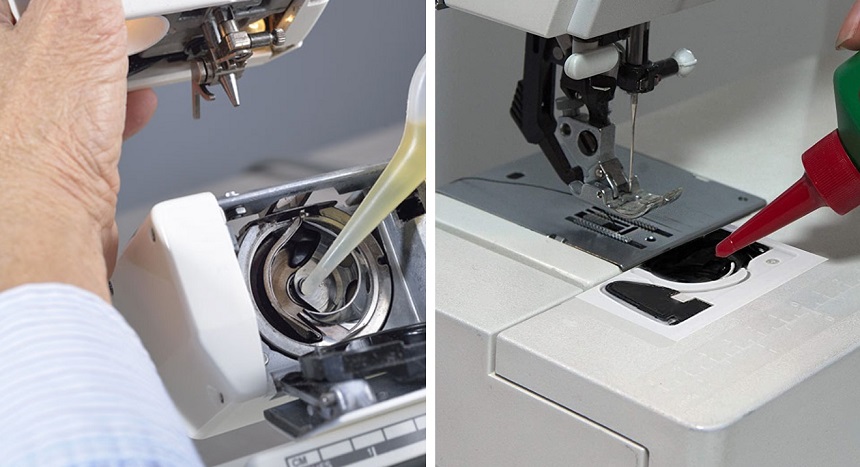

In general, you will oil the moving metal parts of your machine Trusted Source PARTS OF A SEWING MACHINE Today’s sewing machines maximize your sewing experience with their ease of operation and professional results. The parts of a sewing machine are easy to identify. Learn how to. casn.berkeley.edu . This includes the rotary hook, the needle bar, the bobbin area, and sometimes additional pieces. We already covered oiling the bobbin/crochet slot, as well as the foot pedal, so let’s turn our focus to the rotary hook and needle bar.

Before you start, you need high-quality oil. Many sewing aficionados recommend this Lily White sewing oil as a great choice for all machines.

Not every machine has a rotary hook, but many of them do. If yours has a hook, you should clean and oil this spot. To clean, remove any parts that you can, and use that small brush to dust it out really well.

Be sure to turn off your machine before cleaning or oiling the rotary hook. You will simply apply a small amount of oil to the hook and then move it around several times to spread the oil. By a small amount of oil, we mean just 1-2 drops.

The other location is where your needle goes up and down. This space is prone to friction, and materials can also get built up here, just like on your presser foot. Give it a good cleaning before you oil it, just to keep it fresh and clean. Just like with other parts of the machine, simply add 1-2 drops of oil and then move it in several rotations to spread the oil.

Taking care of a sewing machine Trusted Source Sewing Machine Maintenance A well-made sewing machine—traditional or serger, new or old, used often or only occasionally—will sew perfectly for many years if it is given proper care. It may need to be adjusted, or a part may need to be replaced, but a sewing machine that is properly maintained and cleaned regularly seldom actually “wears out. pubs.nmsu.edu can be a lot of work. But if you practice simple steps, it can keep you from having to do a lot of work at once or dealing with issues by avoiding those steps. Here are some great tips to keep your machine in working order.

Learning how to oil a sewing machine really is pretty simple. For most of us, it’s simply remembering actually to oil our machines on a regular basis. These steps should help you keep your machine clean and working well if you use them properly. Taking care of your machine with tips like these is very important to make your machine last much longer overall.

The good news is that when done frequently and correctly, these steps really don’t take very long to complete. Just go through the motions, and your machine will be there for you for many years to come. What is your next sewing project?